JR Automation

SmartAttach™ Automated Nutplate Installation System Product Launch

JR Automation, a global leader in automated manufacturing technology systems, asked us to help them launch a revolutionary assembly system for aerospace manufacturing. Doing it right meant rapidly gaining deep market understanding and working in tandem with their fast-paced product development program.

A Solution to a Time-Consuming Assembly Problem

A typical commercial passenger aircraft incorporates about 25,000 nutplates, riveted-on anchoring points for access panels and other removable components. Until JR Automation developed their SmartAttach™ system, no one else had succeeded in automating the time-, labor- and space-intensive manual drilling and riveting operations for installing nutplates.

Gaining Critical Market Understanding

JR Automation supplied us with in-depth market and technology background, which we supplemented with our own secondary research to frame up an understanding of how best to launch the new product. A key discovery was that the aerospace market was so firmly wedded to conventional rivet attachment technology that it might hesitate to embrace an automation solution that had proved elusive for decades.

Sales Deck for Direct Selling

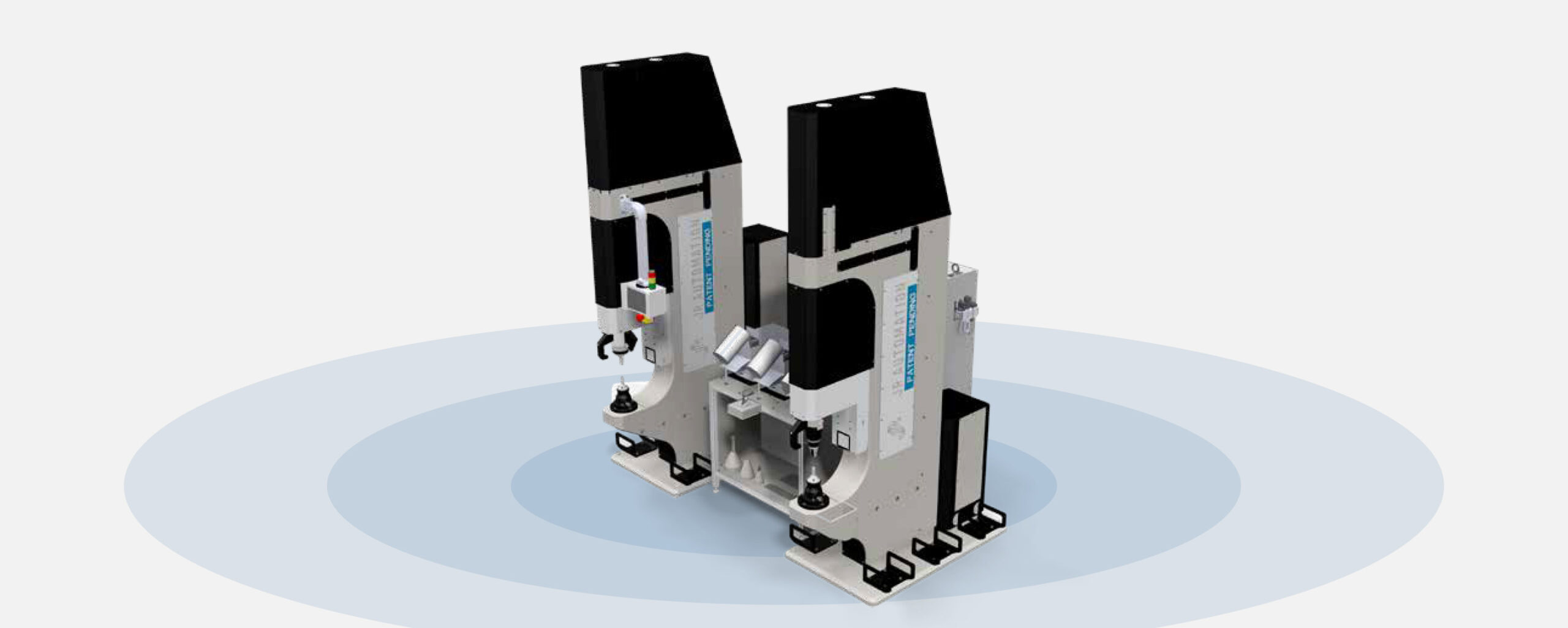

To support JR Automation’s initial market introductions to Tier 1 and Tier 2 aerospace suppliers, we developed a selling presentation that reviewed the technology and market background to underscore the need for a time and money-saving solution to help them solve production backlog problems. As the product neared a market-ready state, we worked with JR Automation’s product development team to refine 3D product renderings to lend clarity and power to the sales presentation.

Website Landing Page to Capture and Funnel Leads

For identifying leads from organic search and proactive communications tools, we created a landing page that summarizes the benefits and key design features of the SmartAttach system. The page includes an embedded contact form for capturing both inquirer and application information.

Literature

We developed product literature for both digital and print distribution. This piece highlights the product’s fast cycle times, greatly improved precision, fast tooling changeouts and floor space reduction benefits, along with its full industrial IoT capabilities.

Have you been seeking a more scalable and sustainable reporting solution?

Share this Case Study